Bottling - The Final Step in the Fast-Paced World of Winemaking The final step of bottling in the dynamic world of winemaking is paramount to the quality and marketability of the product. Now, with advancements in technology and growing changes in consumer preferences, wineries are looking for a more innovative wine bottling solution to compete. The most current methods and technology revolutionizing this pivotal period of winemaking are explored here.

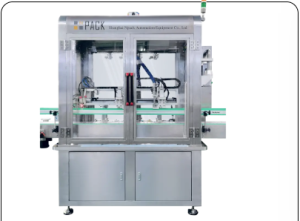

Automated Bottling Lines

Bottling lines that are automated are a revolutionary step forward when it comes to the speed of producing wine. New systems are capable of doing 20,000 bottles an hour versus a traditional line that does 1,000. The speed in these lines will facilitate not only increased productivity but more accuracy in filling, corking and labeling reducing human error and product loss. These innovations include multi-stage filling systems that control the wine's contact with oxygen to extend shelf life and preserve flavor.

Eco-Friendly Packaging

As consumers continue to take an interest in green shopping, sustainability is also increasingly becoming a key concern within the wine industry. To address this, organizations are turning to biodegradable and curated products as items for water bottles and packages. Wineries, for instance, have started adopting bottles made from more than 85% recycled glass or experimenting with plant-based plastics that biodegrade, instead of off-gasing. In addition to appealing to eco-friendly customers, the carbon offsetting helps wineries reduce their environmental impact.

Smart Bottling Technologies

This constitutes a game-changing proposition in the bottling line environment with smart technology integration. Real-time monitoring of humidity, temperature, filling speed and other factors using sensors and AI algorithms to adjust the process on-the-fly for best outcome. So the technology secures proper quality for each bottle of wine, an important issue for brand reputation. Smart bottling lines even can forecast maintenance requirement will certainly minimise downtime and cost of operation.

Customization at Scale

Growing custom bottling trend As the custom market continues to expand, wineries are boldly thinking outside the case to go even farther. With the help of innovative technologies in advanced packaging solutions for bottles, label changing on the same line and even the changing of the shape of the bottle on the same line are not that big an issue anymore. As a result, wineries can now offer WS Labels for specific events and create limited-edition wines, driving customer engagement and targeted marketing.

Enhanced Quality Control

The extraction of wine is essential, wine bottling equipment includes advanced inspection systems. Before products ever get used by you, products are scanned by things like ultra-high-res cameras and even the Jedi Eye Infrared sector scan to look for even small flaws in bottles, caps, or labels. These systems ensure that customers get the highest quality, and are helpful for wineries to hold their authorization.

Simplified Delivery and Tracking

In addition, new custom packaging lines smoothly interface to existing logistic and tracking systems to provide improved inventory management and more rapid response to market needs. Using RFID tags and blockchain technology, bottles can be tracked from production to consumption in a transparent, tamper-proofed manner. This also helps in better stock management and real trust from consumer towards the brand.

These advanced technologies and solutions can be crucial for wineries to improve overall efficiency, sustainability, and product presentation within their wine bottling solutions. Consumers continue to flex their muscles and the competitive environment amplifies, meaning that these sophisticated solutions are now more than a nice-to-have but a must-have for wine industry success.